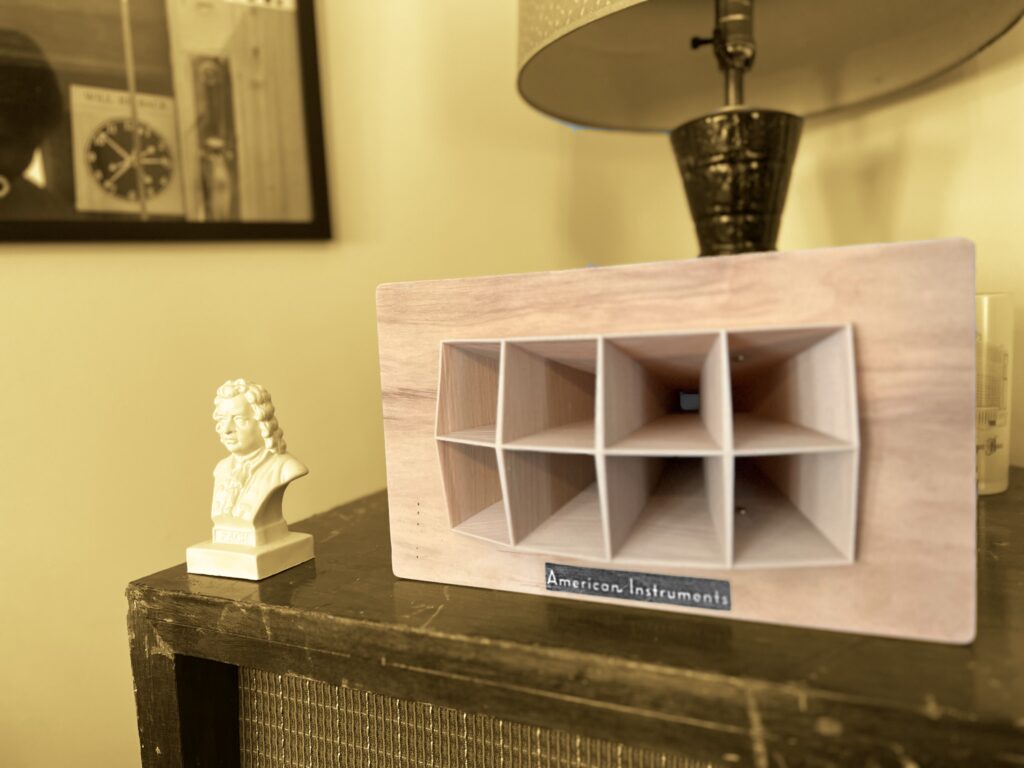

The clearest sounding small horn ever.

We’ve owned them all. (vs 800hz sized 1940s~80s era, incl. WE (32A, KS 120xx,), Altec (811,808), JBL, TAD, Jensen,etc) Unlike others, the H1000 was Designed and Imagined for High Fidelity audio from inception.

That is, HiFi for the Home as It Was Dreamt in the Late 1940s.

This is the era of low-powered tube amps, for high speed presence and detail.

Crafted From aged materials, for authentic sonic performance.

The H1000 delivers effective sound and the reasonably broad coverage of larger horns, while avoiding the beaming and narrowness typical of smaller designs. Its compact, straight design ensures clarity without the terrible, squawky coloration inherent in re-entrant, angled or radial horns. These other horns (often featuring, cheeks, lips and 90 degree bends) were voiced for public address systems ( examples Ampex, JBL, or Altec 811).

While only 12″ wide (with frame), the H1000 outperforms horns twice it’s size. It’s also a major upgrade from mini horn’s, (like JBL’s conical “potato masher” and other multicells, such as found on the Altec 604).

What does this horn fit?

The H1000 is predrilled to fit most common USA and some European 1″ compression drivers. Including all 2 bolt Altec-Lansing (800 series) and 3 bolt JBL (175 series) pattern drivers. The holes easily accommodate M6 or 1/4-20 studs.

Crafted Cork Gasket with New Old Stock Acoustical Silk

The same natural, rectilinear pattern material used in the 1930s-1940s by companies like Jensen, Western Electric and Lansing Sound for the aperture of the microphones and drivers .

Wooden Baffle Frame made from antique, reclaimed plywood of the 1940s and 1950s

Vintage plywood forms the front frame or “baffle” of the H1000. This forms non-structural front surface, creating the same wavefront area, which can be positioned on the same plane as most any woofer. This 60-80 year old plywood has layers of old growth domestic wood varieties, along with no longer used water sensitive, super hard organic glues.

Wood like this is no longer manufactured, so we source it from old & closed shops across small-town America.

Assembled with vintage 1940s brackets and NOS Brass Screws and bolts.

American Instruments audio accessories and devices are made with old world sound quality and feel in mind. Modern hardware would not do. Each horn is hand-assembled with the finest possible Imperial threaded, brass, and copper hardware. The slim nickel plated brackets (treated with gold tint varnish) are NOS from the 1940s.

Composite wood horn prevents ringing.

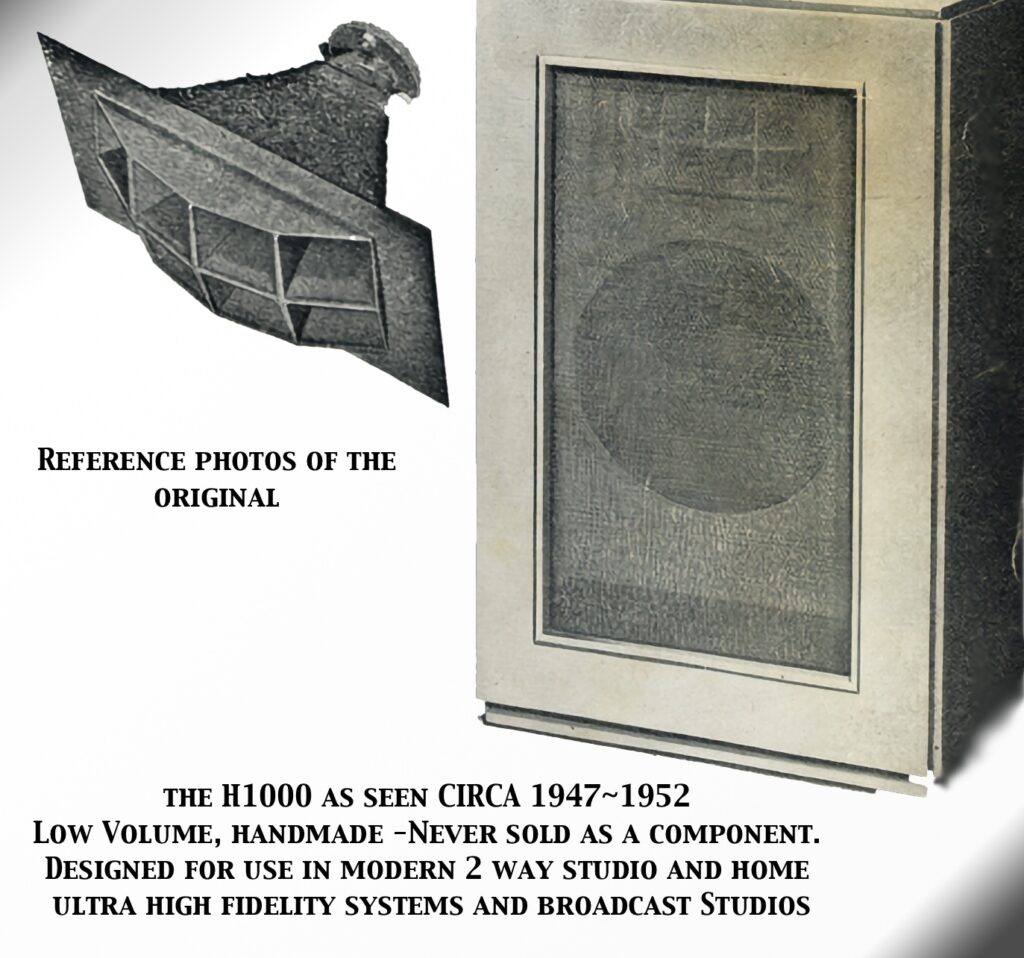

All horns, no matter the design, or the physical size (most horns are much larger) have coloration or drawbacks. The H1000 has remarkably (almost) none. This was born of countless hours of listening, by Jim Lansing in the mid 1940s. 50 years later, Walt and Early (a handful of audiophiles who found 1940s originals) began 2 way system experiments. It became immediately apparent the straight (non bent), very carefully proportioned size held magical qualities. We have maintained the original sound and performance, while reducing the glare and resonance of the original’s soldered tin metal.

Versatile!

Excellent for Set-Top Use, retrofit, in cabinet builds. Many possibilities.

Purposefully made in a delicate, and lightweight method, the H1000 will excel as a simple, top-sitting addition to a variety of low frequency cabinets. Build-in to cabinets is fine, with driver support. The horn flush will maintain positional time alignment with most 15″ woofers.

Most easily balanced with a Single or Dual 15″ woofer (s) crossed over at about 1200hz. It’s also possible to use twin 12″ woofers. While smooth — this small, yet powerful horn can still overpower a single 12′. It can easily be attenuated with resistors or an L-Pad in most situations.

Just like the 1940s, specs are simple & honest.

Quality and Performance are high.

Unbent Expo Horn geometry conservatively rated to 1000hz, optimally crossed over at 1200hz. Suitable for small, medium and large rooms. Extremely polite and detailed at low levels. Will work with 6dB, 12dB and most other custom crossovers. Excellent clarity and dynamics at loud levels. Unrivaled for it’s size!

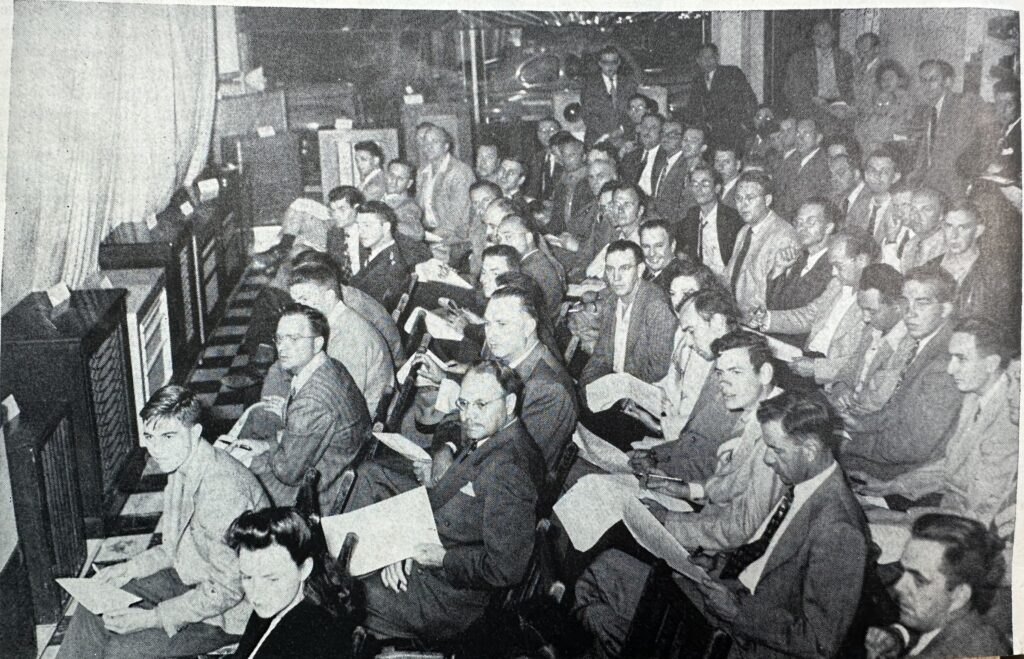

- Speaker evaluation event circa 1948.

- Western Electric 753 2 way (front left 1st visible)

- Early Klipschorn in far left /rear corner

- H1000 2 way, “D1002” system (front far center rear).

Born in an era of “listening first”.

The H1000 was designed sometime between 1945~1946. The builder had the knowledge, the need and his ears. Drawing on knowhow gained over 20 years of making cinema sound systems; a pioneer of multicell and compression driver technology. This is one of the last horns concieved and voiced using prewar (1930’s) methods. Like other designs of it’s day…it started with exponential calculations and a rough idea of frequency range and coverage angle. The rest was pure intent and thousands of hours listening…that’s not the procedure in our modern era. Thanks to the toil of yesteryear, key elements were nailed, giving this ultra small horn performance far beyond it’s tiny footprint.

The intent, by 1947 was to perfect the compact 2-way horn system (the Lansing Iconic until the was champ (1935~1945), bringing dynamic & wide range sound into the living space, for the cutting edge and disruptive home HiFi craze as it began, after WWII.

Each H1000 horn is handcrafted in Virginia, USA. Reclaimed antique & old world materials are throughout.

- The old growth, hide-glue plywood (patterns, finish, species and condition vary) has been reclaimed from 1930s~1950s commercial and residential structures. (Furniture and cabinetry from closed or abandoned small towns)

- Hardware is Solid brass and nickel and bronze.

- Horn is made of a solid, void free high wood content composite, suger cane binder (non-petroleum) in origin. Similar in sound and performance to 1930s molded (once referred to as “moulded wood”) products. This light, hard, brittle material gives a signature, crisp and present, but not overly bright sound.

- Natural cork and fiber gasket, with vintage (from old stock) Western Electric high symmetry (acoustic graded) silk, in center for dispersion enhancement and dust block.

- It’s not just the feel, and not just the look ~ The sound is there too!

“Had my friend over last night for a listening session. He is a jazz trombonist and writes my marching band shows. He loved the H-1000’s said they sound great with brass instruments.”

Customer / Owner in Georgia, USA

(Previous horns include Altec 811 and JBL 1217-1290 “Potato Masher”)